An innovative solution in the material science industry must fulfill two requirements: it must process adequately under industrial process conditions and have the desired properties at the completion of process. The physical and chemical phenomena that take place during the application process are highly complex. Their kinetics must be perfectly balanced and all the reactions must be completed to achieve the desired properties. Often the laboratory conditions are different from the industrial process conditions. Many times, even if all the reactions complete in the lab tests, the industrial trials fail because the kinetics of certain phenomena is either too slow or too fast under the industrial application conditions.

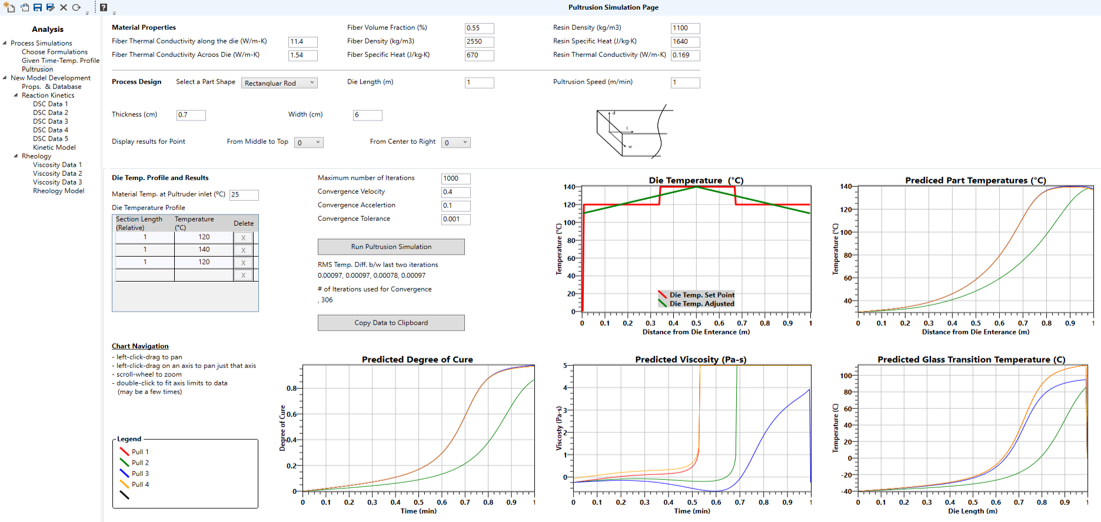

Intugent provides customized software to develop process scaleup models. These models are specific to a formulation and are trained using lab data. Once the kinetics and rheology models are trained, they can be used later on to simulate the industrial applications of that formulation. Researchers can train model by themselves using the lab data and simulate the industrial process. For example, Intugent's I-Rheo software can simulate industrial applications of thermoset polymers in various processes such as filament winding and pultrusion. The figure below shows a screenshot of pultrusion simulation.

Researcher does not need any background in math modeling or finite element analysis.