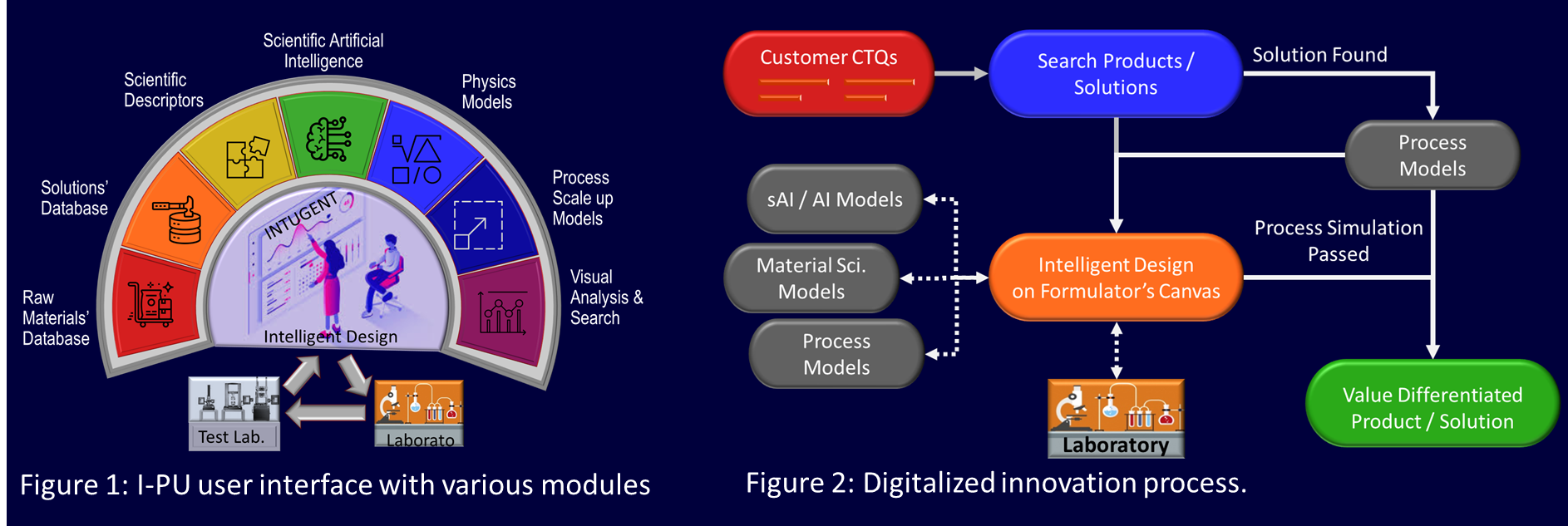

I-PU is a Digitalized Innovation Process (DIP) software for rigid polyurethan foam applications. It can help engineers and scientists to speed up the innovation process and improve the odds to be successful in the very first industrial trial. I-PU was first commercialized in 2023. It includes all the digitization and digitalization tools needed for the innovation process. All these tools are seamlessly integrated with the user interface shown as Intelligent Design Canvas in Figure 1.

The design canvas is linked to historic formulation / solution database as well as visual data analyses and search tools. Before getting started with any new innovation, researchers can search the database for preexisting formulation / solutions. These tools can also help researchers to analyze the portfolio and search for white spaces.

If a new innovation is needed, design canvas provides a natural work platform. It is linked with the raw materials' database. As researchers design new formulations / solutions, scientific Artificial Intelligence (sAI) models and physics (material science) based models in I-PU predicts the final properties at the completion of reactions. Besides the final properties, I-PU also calculates many scientific descriptors such as crosslink density, average functionality, average equivalent weight, and others. In order to maximize the probability to be successful in the very first industrial trial, researchers can use lab data to develop process scaleup model, save these models, and use them to simulate the industrial application process. A schematic of the innovation process is shown in Figure 2.

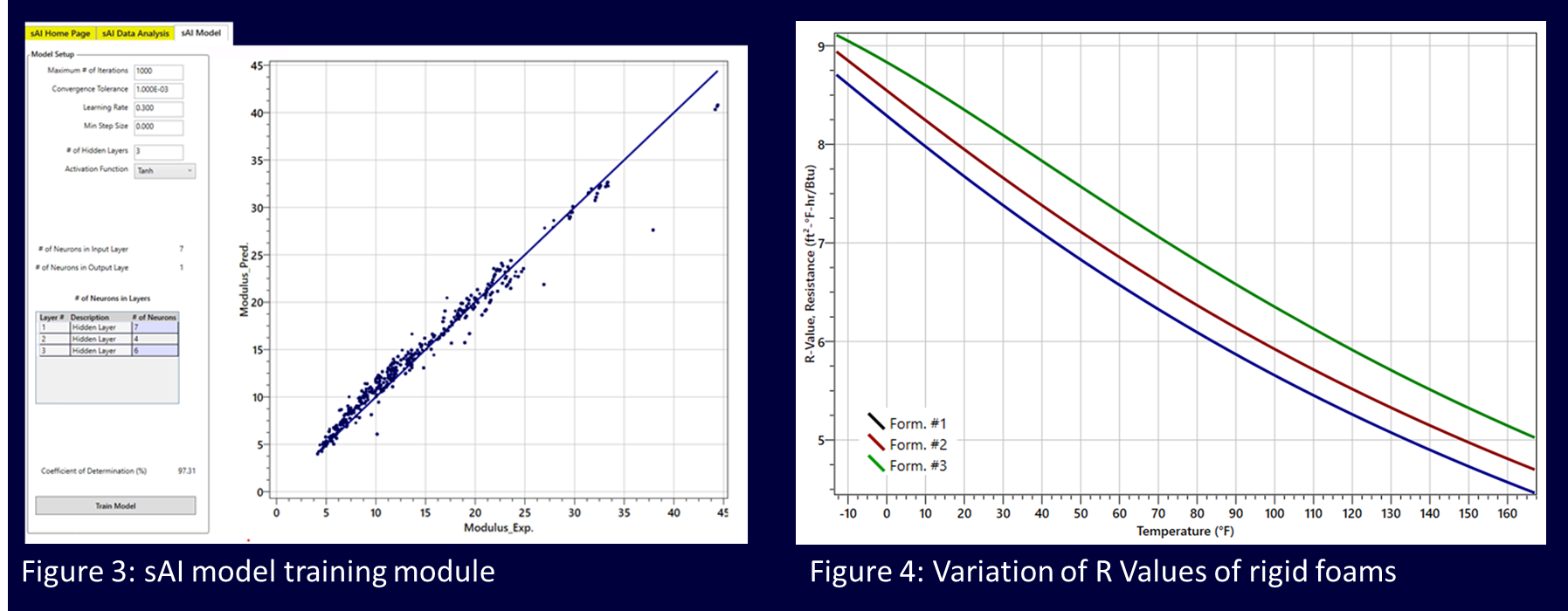

The digitalization tools such as sAI models can be trained by engineers as additional data is available. No background in AI or math modeling is required. Figure 3 shows the sAI training module. It shows comparison of predicted and experimental values of Young's modules for elastomeric polyurethanes. Since, the real-life experimental data was not available, the experimental data was synthesized using material science-based models.

Figure 4 shows predicted R Values of rigid polyurethane foams from a physics-based model for various formulations. Researchers can investigate variations of R Values with temperature, cell size and foam density.

I-PU is designed for excellent user experience. It has an optimum balance of edge and cloud computing for high computing efficiency and data security. It is customized for each partner and the industry segment.