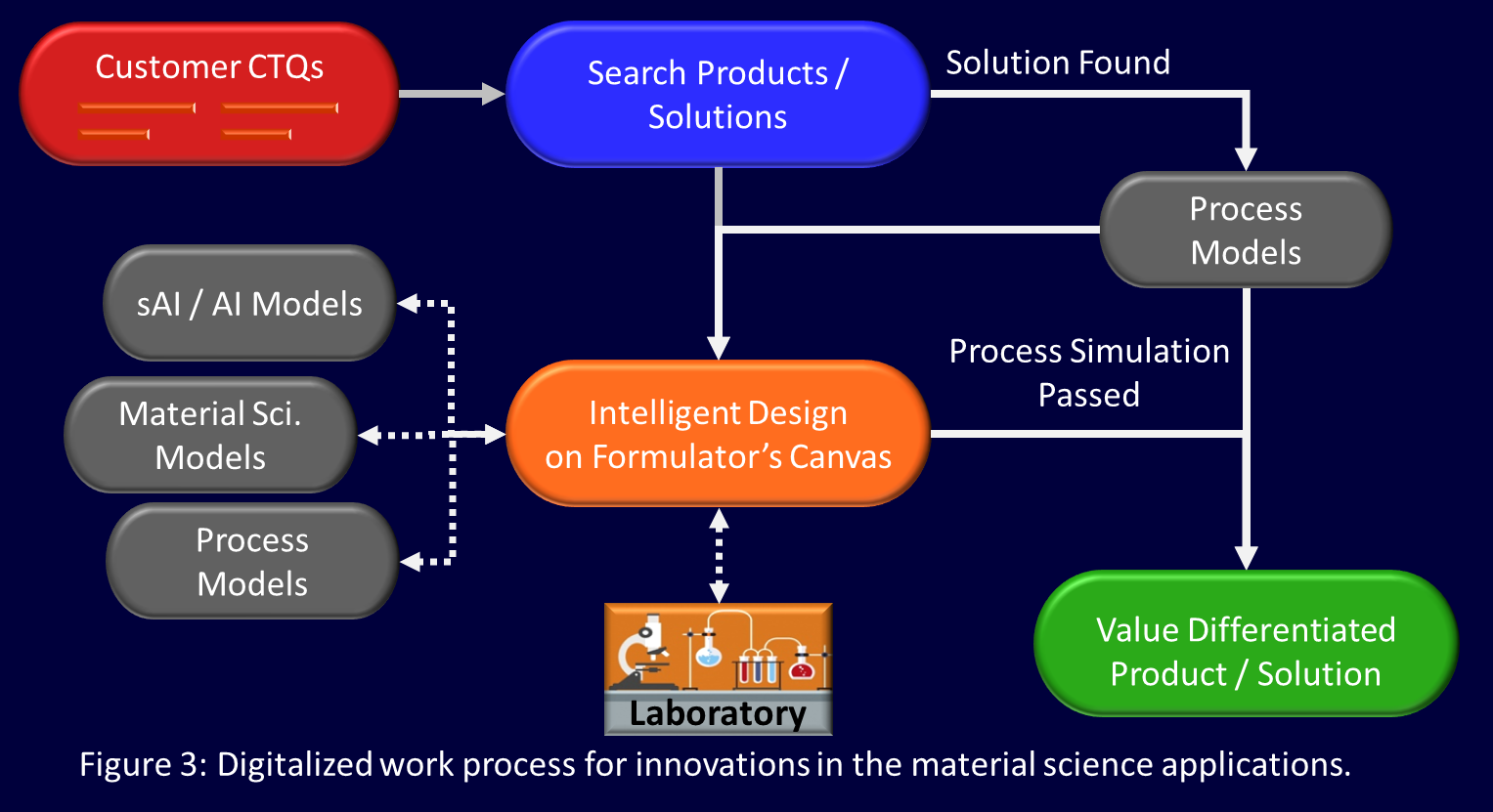

An innovation is a novel approach to solving a problem. A new innovative solution in material science application often requires mixing a number of components selected from a range of material families such as key reactants, surfactants, catalysts, pigments, blowing agents and other additives. As these materials react, a number of physical and chemical phenomena take place. These phenomena must be carefully balanced to achieve the desired properties not only at the completion of reactions, but during the processing as well. A schematic of various chemical and physical phenomena involved in new polyurethane material development are shown in Figure 1.

Often the lab conditions are different from the industrial application conditions. Therefore, even if kinetics of various phenomena is perfectly balanced and desired properties are achieved in the lab, there is no guarantee that the desired properties will be achieved during the industrial application as well. It may take many trials and errors before the very first successful industrial trial. As a result, the innovation velocities in material science applications are slow, developmental times are long, and costs are high.

Digitalization is the process of using digital technologies to make an impact to a business’ bottom line. The digital transformation of the innovation process provides a digital platform to researchers where they can design new solutions. As they design new solutions, they get real-time feedback from various scientific Artificial Intelligence (sAI) models and material science math models about the final properties of the material. Researchers are also able to simulate the industrial application using Process Scaleup Models. The end goal is to increase the velocity and quality of the innovation and improve the probability to be successful in the very first industrial trial.

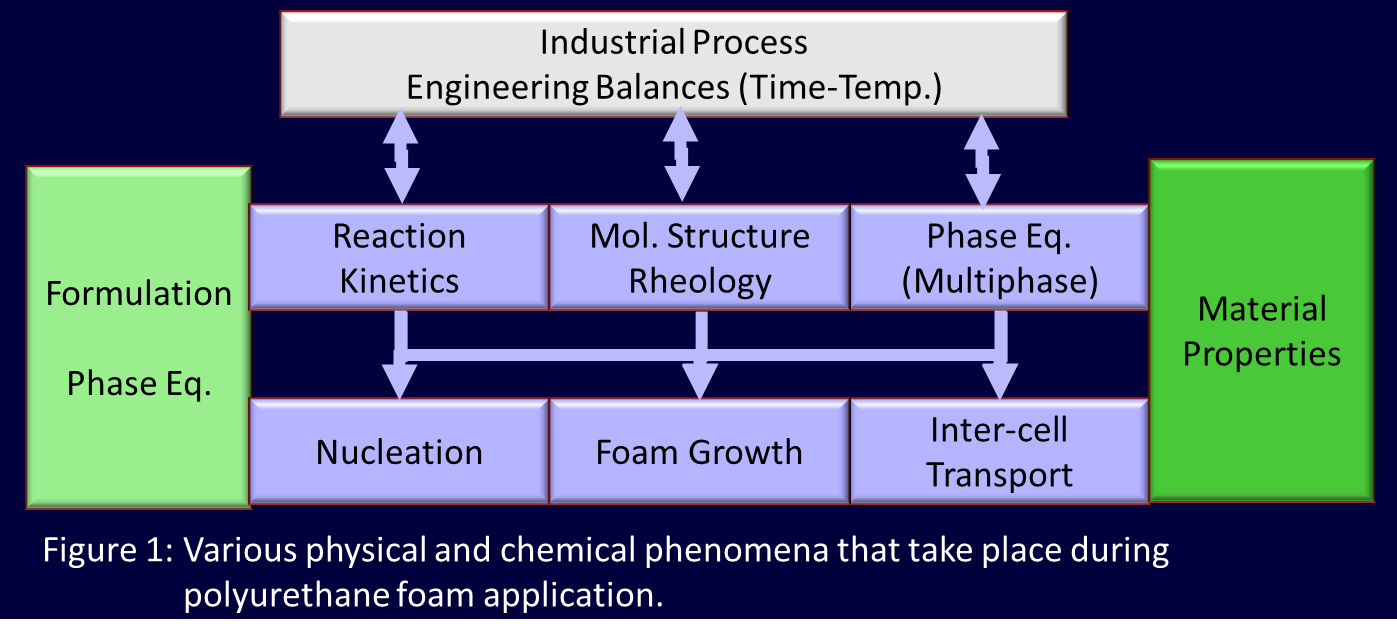

Digitalization is built on top of Digitization and Digitalization. Digitization is a process of capturing information and data in digital form. To make the most of it, data must be captured as it is being generated. Digitalization is the process of using digital data and digital technologies to develop digital tools that can guide researchers. Physics based math models, scientific artificial intelligence models, process scaleup models, searchable databases of past commercial and experimental data, are examples of digitalization tools that can help in reducing the developmental times and costs.

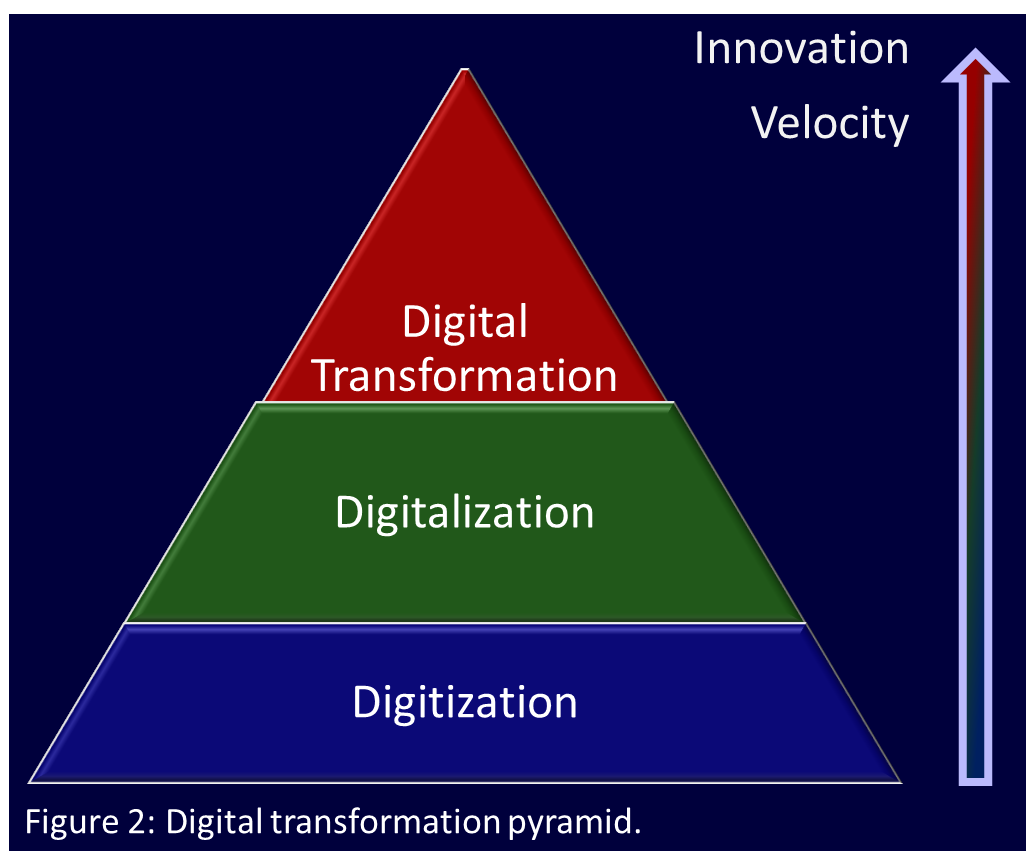

Intugent provides a comprehensive Digitalized Innovation Process (DIP). A schematic of DIP is shown in Figure 3. The process leverages various digitalization tools. A few examples are given below.

The search tools include visual data analysis as well as digital search. Visual analysis tools can also help researchers to find new white spaces for new innovations and inventions. Material Science Math Models, AI, and sAI models predict properties achieved at the completion of reactions. sAI models are special kind of models that combine machine learning with material science models. Process scaleup models are science-based models specific to a formulation or solution and are trained using the lab data. These models are used to simulate the industrial application and can also be used to troubleshoot and optimize the industrial processes.

A formulation or solution is found only when it can provide the desired properties at the end of the application process, and it can also complete the reactions as desired under the industrial process conditions.