I-PU

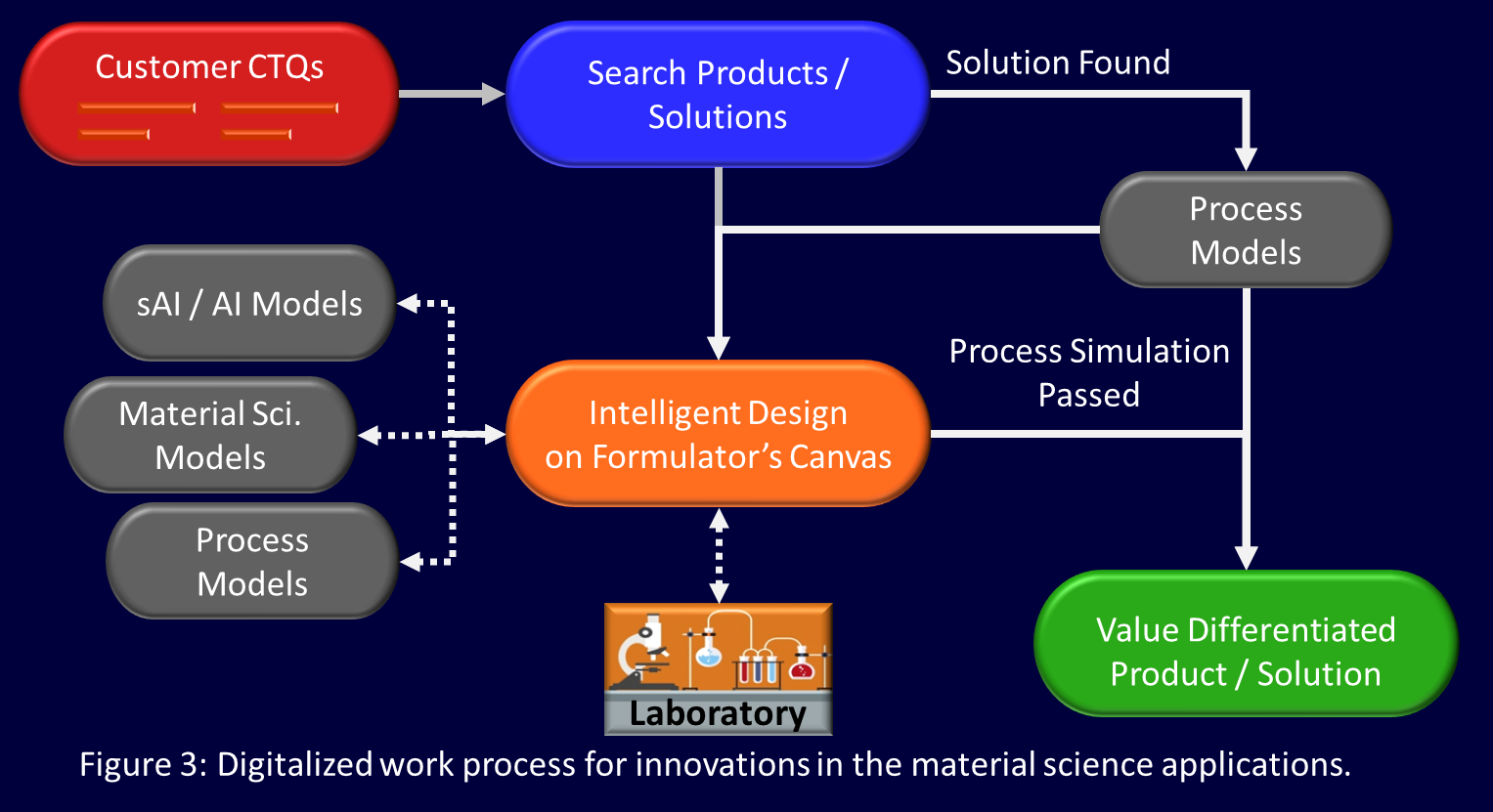

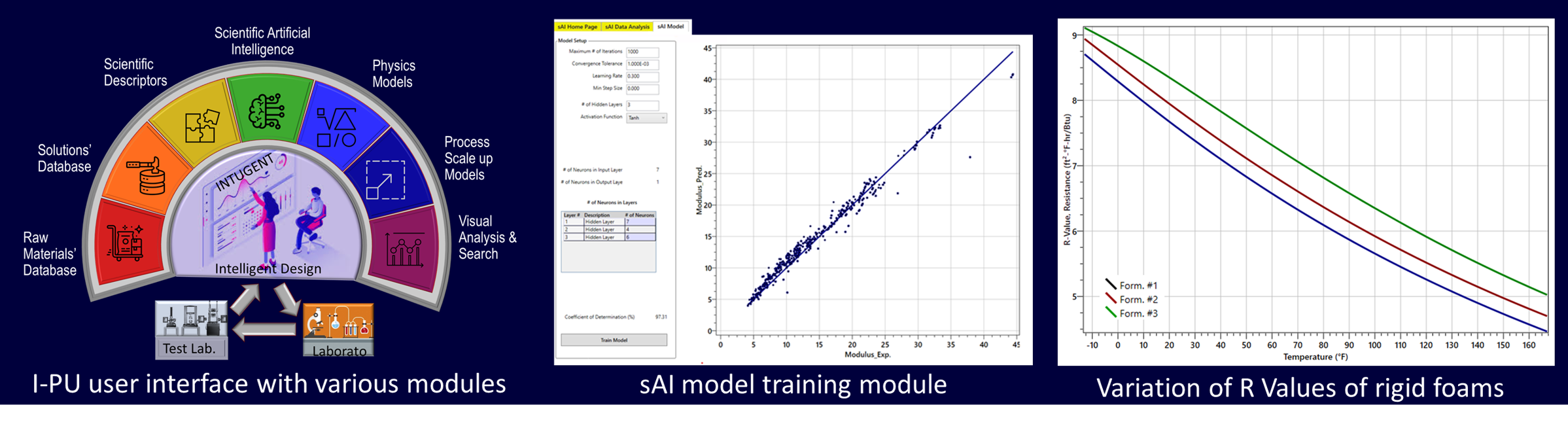

I-PU is a Digitalized Innovation Process (DIP) software that can help engineers and scientists to speed up the innovation process and to improve the odds to be successful in the very first industrial trial. I-PU was first commercialized in 2023. It includes all the digitization and digitalization tools needed for the innovation process in the polyurethane applications. All these tools are seamlessly integrated with user interface shown as Intelligent Design Canvas in the figure below.

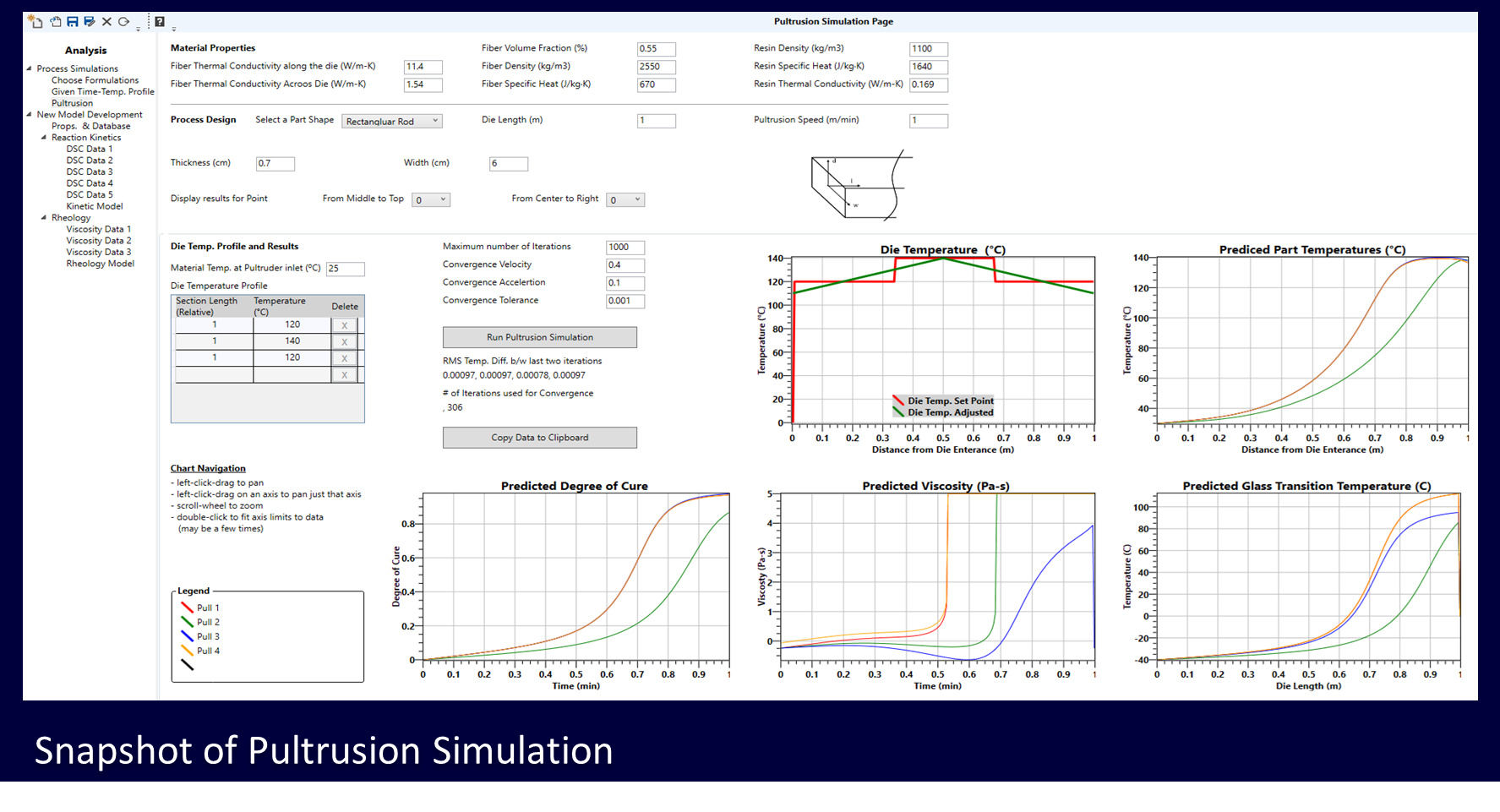

Visual data analyses and search tools allow researchers to search for preexisting formulation / solutions. Using Process Scaleup Models, they can ensure that the formulation will process as desired under the industrial application conditions. If a new innovation is needed, design canvas provides a natural work platform. The scientific Artificial Intelligence (sAI) models and physics-based (material science) models, such as R-Value model, predict the final properties at the completion of reactions. Using Process Scaleup Models, they train models for new formulations, save, and use them to simulate the application process under the industrial application conditions.

Learn More About I-PU